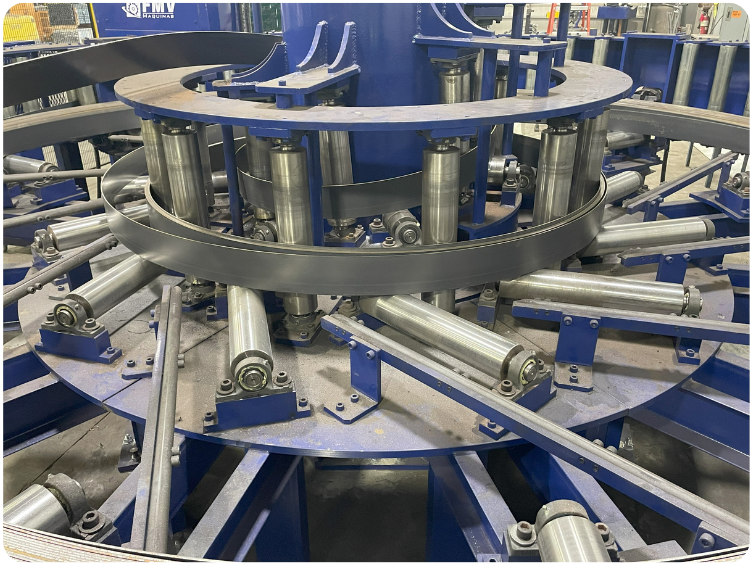

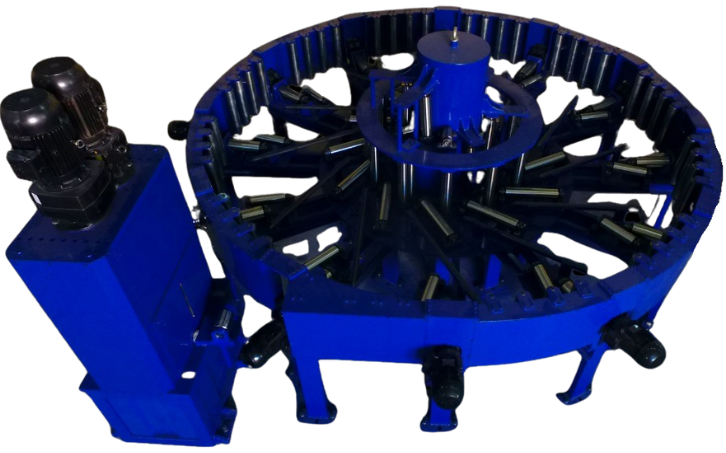

Behind every efficient tube and pipe operation are the unsung components that set the tone for productivity, precision, and safety. Rafter offers a range of supporting entry systems — like turnstiles, peelers, flatteners and strip joiners — that work behind the scenes to keep material flow steady and transitions seamless. These systems are built to handle heavy-duty demands while reducing manual intervention, streamlining coil prep, and maintaining the integrity of the strip before it ever reaches the mill.

Turnstiles manage multiple coils for faster, safer staging and changeovers. Peelers prep the strip for welding by lifting and straightening coil heads. Flatteners eliminate unwanted strip memory or curl, helping to ensure precise downstream forming. And strip joiners — whether mechanical or welded — connect coil ends with minimal downtime. These tools may not grab headlines, but they make all the difference in line continuity and long-term performance.