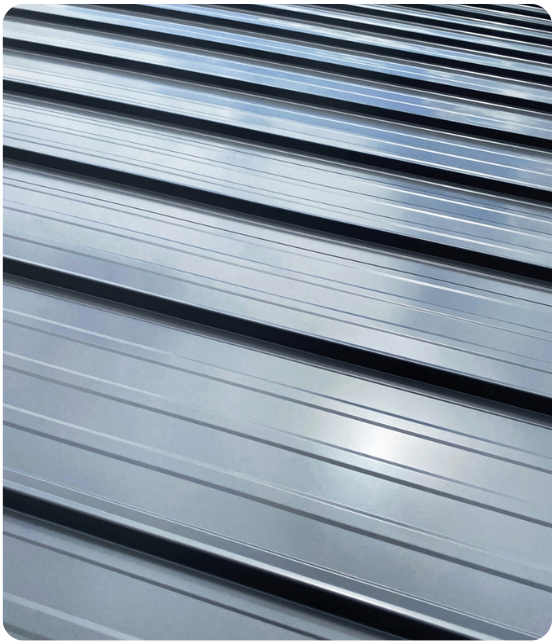

Shaping what’s next in rollforming.

Engineered for precision, built for versatility – our rollforming mills deliver consistent performance across profiles, industries, and demands.

Standard Rollform Mills

Designed for versatility and scalability, our standard rollform mills accommodate 1½″ to 4″ arbor shafts with adjustable roll space and vertical alignment. These raft-style mills allow customers to run multiple profiles on a single line, optimizing capital investment while maintaining quality performance.

Rollformed Metal Building Products

Purlin Rollforming Lines

Engineered for roof structure components, our purlin lines produce C, Z, U, and eave struts with fast changeovers – some in under 5 minutes – thanks to precision controls and hydraulic tooling. Whether manual or fully automated, these lines deliver high-volume production with consistent accuracy.

Angle & Channel Rollformers

Leveling out curl and crossbow in the strip material, our flatteners ensure perfect flatness before it enters the forming mill. Paired with shear welders, they promote consistent feed and high-quality weld joints.

Door Frame Rollforming Lines

Our end-to-end door frame systems roll, punch, cut, and stack frames – including steel, bronze, or fire-rated profiles – without stopping production. Featuring cassette tooling and flying shears, they deliver clean, repeatable cuts (45° or 90°) at production rates up to 30 m/min.

Lock Seam Mills

Lock seam rollformers create snap-together or button-lock seams—ideal for roof panels, ductwork, and door frames. With speeds up to 65 fpm and tooling for male/female locking, these mills streamline assembly with flush, secure connections.

Interested in adding any of these systems to your operations?

Reach out to us—we'll help determine the right rollforming solution to optimize your production and drive long-term success.

CONTACT US