Intensifiers

Filling and Purging

Pipe Alignments

Flush Out / Wash Out

Clamping

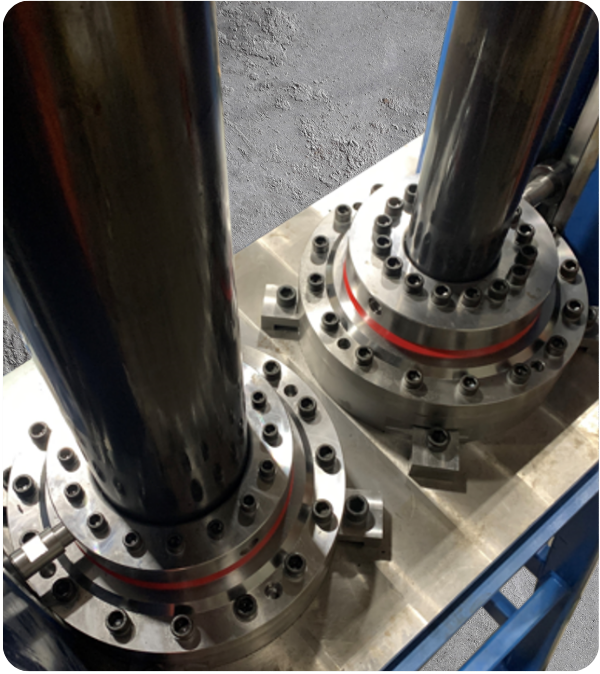

Tooling

Seal Optimization

Drifting

Revampings:

Test Head Removal Fixture

Test Head Redesigns

Tooling Updates

Once a pipe leaves the mill, precision and performance aren’t finished—they’ve just begun. Rafter’s finishing product suite is designed to ensure every segment of the line—from straightening to bundling—meets the highest standards of dimensional accuracy, structural integrity, and functional readiness. With cross-roll straighteners, hydrostatic testers, leak and collapse testers, and beveling/facing machines, we tailor your finishing line to your product specs and industry standards, reducing rework, enhancing quality, and optimizing line efficiency.

On top of that core process equipment, we offer specialized systems for handling and assembly: rotary cut-off units, flush/blow-out stations, pipe drifters, threaders, coupling screw-on, thread-protector applicators, interconnecting handling, packaging, and bundle systems. Whether you’re working with structural tubing, energy pipe, or mechanical conduit, Rafter’s finishing tools integrate seamlessly to deliver ready-to-ship, spec-compliant products. Built for durability, versatility, and maximum uptime, our finishing solutions reflect the innovative precision customers expect from the Rafter and Kraft Werks legacy.