Production & Product Specifications

Outside diameters from 3/16″ to 12-1/2″.

Wall thicknesses from 0.010″ to 0.625″.

Outside diameter-to-wall thickness ratios from 6.5 to 100:1

Production speeds over 1,000 ft/min.

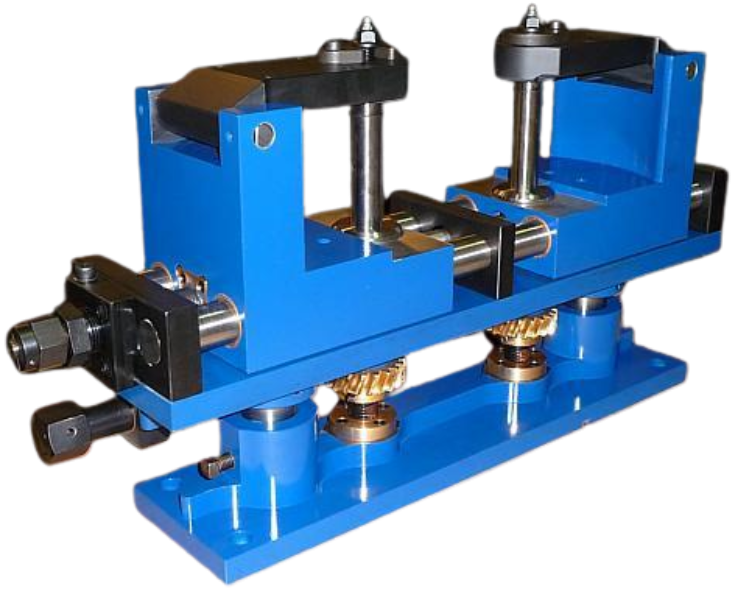

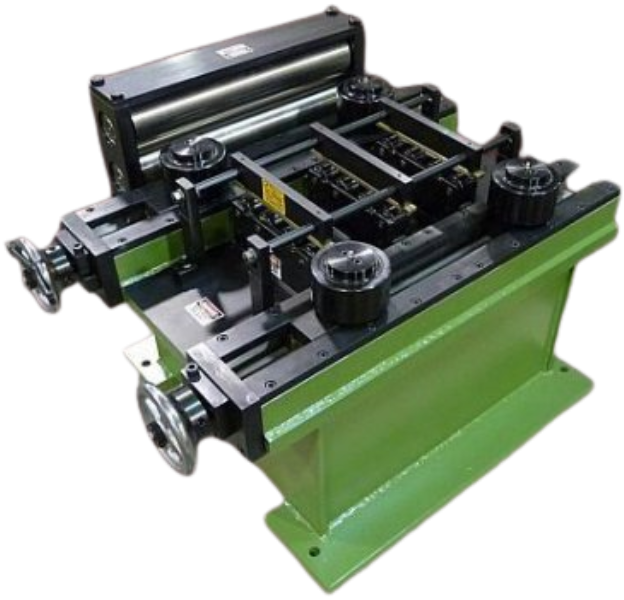

Roll stands are designated by the roll shaft diameter. For example, our RT-1000 stand is a 1″ shaft machine, and our RT-8000 stand is an 8″ shaft machine. Our single-point adjustment (SPA) top roll shaft adjustment has essentially become a standard feature on all new mills. It also can easily be retrofitted to your existing mill – whether it’s a Rafter machine or not.

The Rafter SPA design can be further enhanced with the addition of power adjustment. This can be a simple open-loop, operator controlled feature or a full-blown, closed-loop, recipe-type setup system. We’ve done them both!