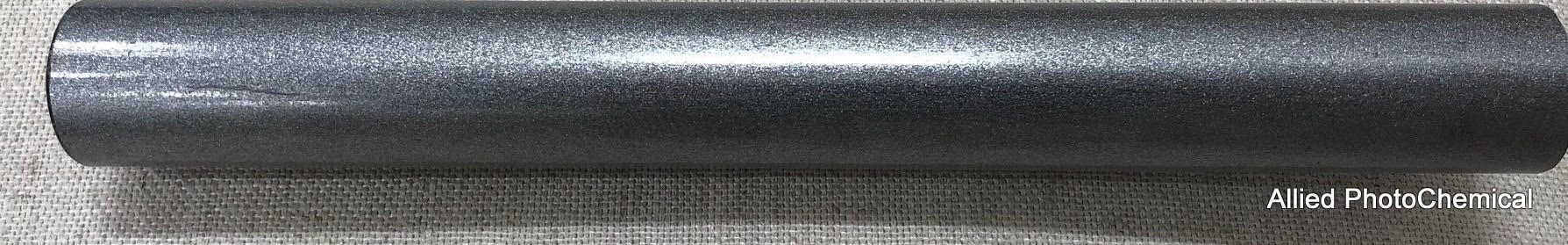

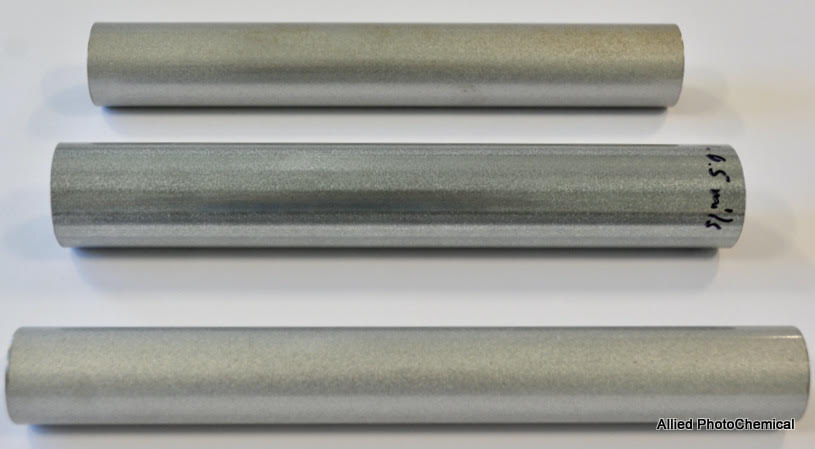

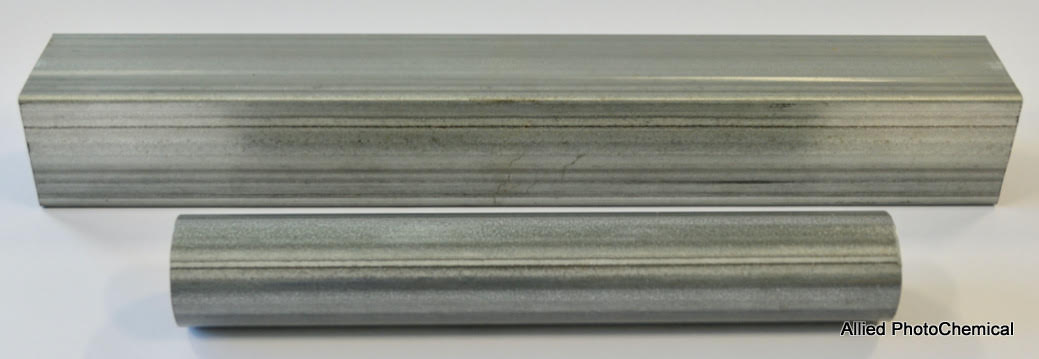

Anti-Corrosion Coatings

In association with Allied PhotoChemical, Rafter now offers UV and water-based curable coatings for the tube & pipe, and rollforming markets. The Allied PhotoChemical coatings are resistant to corrosion, extremely flexible, offer great adhesive properties, are fast curing, and can be custom color matched to suit your needs.

UV Curable Coatings:

UV Curable Coatings can be applied and fully cured in less than twenty (20) feet of floor space. Much faster processing speeds (up to 500 FPM) can be achieved, with minimal floor space requirements, while eliminating all Volatile Organic Compounds or VOC’s. Advantages of adding a UV curable coating:

- Very small/in-line footprint

- Faster Line Speed – Up to 500 feet per minute

- Instant Cure Time – Immediate bundling

- No Volatile Organic Compounds or VOCs – Zero

Water-Based Coatings:

Water-based coatings can be implemented with small physical footprint, fewer VOC’s and less overall capital costs while delivering good corrosion protection and appearance. Additionally, these coatings are great for protecting finished products and have fast drying times. Advantages of adding a water-based coating:

- Fewer VOCs

- Small footprint

- Odorless and no yellowing

- Lower cost of capital equipment